Preparation For Main Pour

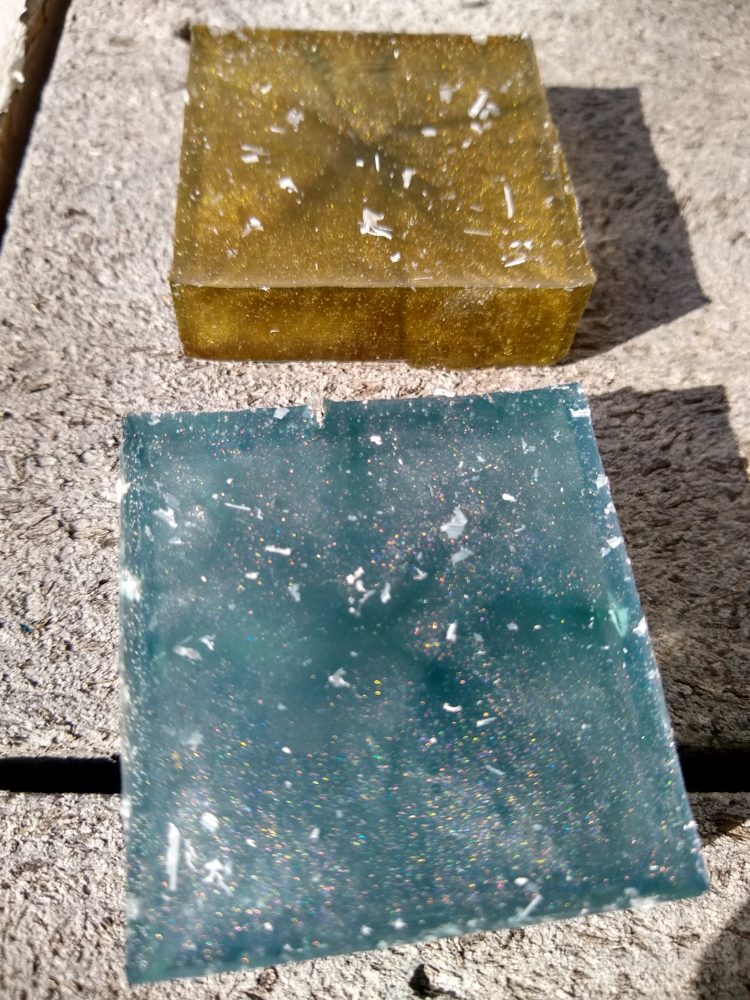

The couple of things that I had to do in preparation for my main pour were to figure out the main color I wanted to do, seal the wood, and prep the wood and the mold together. The first picture you see below are two practice squares of resin used to test powder pigments used for coloring. In the top square I used a bronze powder along with a translucent green and blue dyes. The bronze powder completely overtook the green and blue color. I instantly knew I didnt want this because I wanted the color of the resin to be ocean like. The bottom square was a mix of white and purple powder pigments along with blue and green translucent dyes. I really liked how the purple and white shined in the blue, but the overall blue color was too dark for me. So I knew I wanted to do a lighter color.

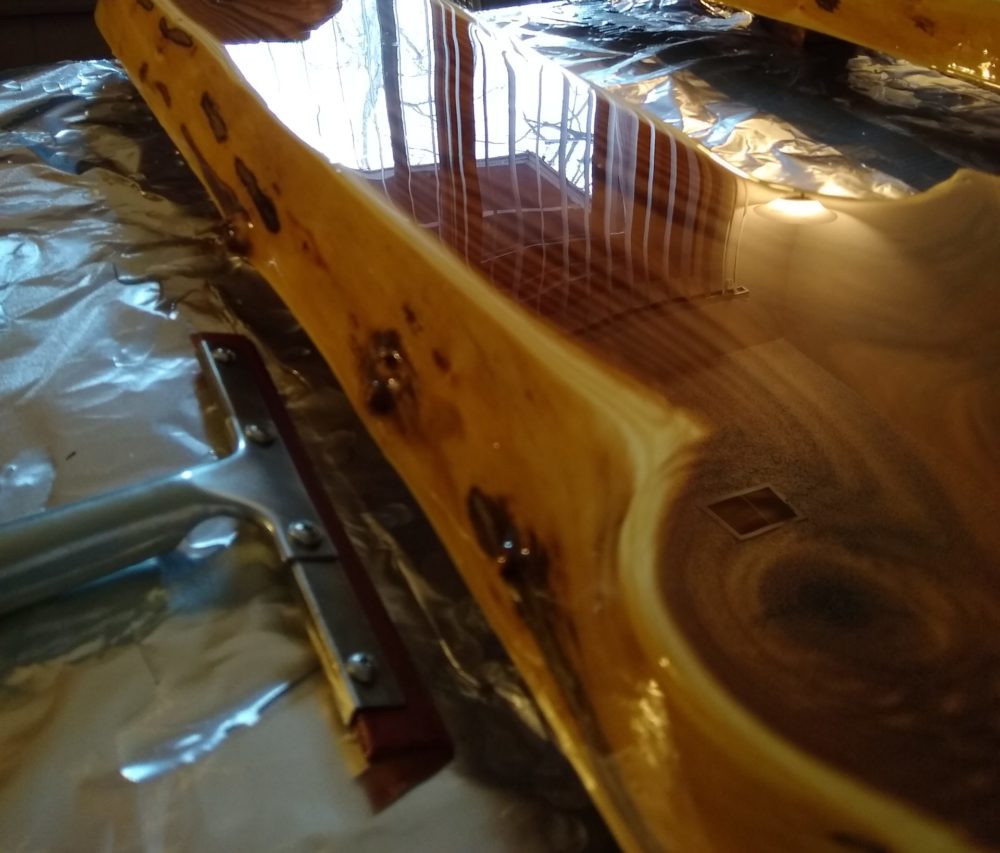

In the picture above and to the right you can see the final layer of epoxy poured over the wood in order to seal it so there would be no bubbles that would come out when I did the main pour. The finish looks very mice. But I had to sand it to level it and so that it could mechanically attach to the main pour.

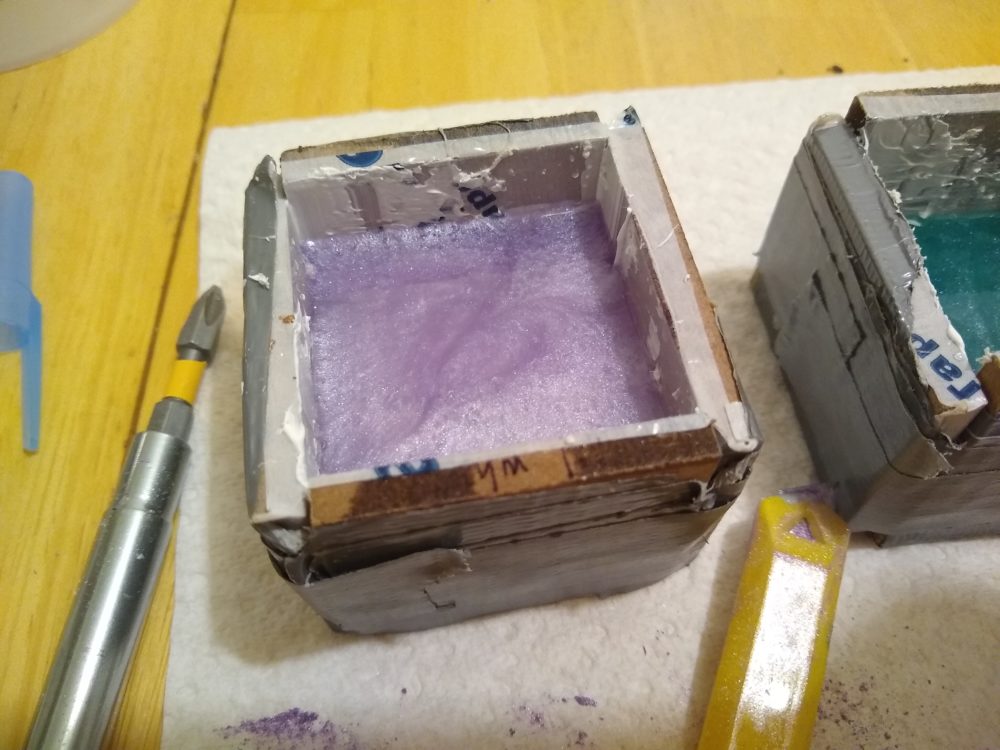

After the wood was prepared I practiced some more with coloring the resin. Below you see the two colors that I decided I liked and the ones that I would most likely use on the main project. The left picture below was created by pouring a resin in that was tinted with green and blue translucent dye. Then the purple/white mica powder resin in the left picture was poured into the translucent. This multiple color pour created the exact look that I am going for. I decided I wanted my table to have the look of the blue/green square in the picture below and to the left.

Once I knew what color I wanted to do, I needed to prep the wood and the mold together. Please check out my previous posts throughout the semester in order to see how I built the mold and prepped the wood in the machine shop and at home. In order to proceed, I leveled the mold and shimmed it with folders in order to get everything as level as possible. Then I placed the wood in the molds to check their positions. I then took them out and mixed a little bit of epoxy resin and poured it over the bottom of the mold andplaced the wood in. I then placed other wood and clamps in order to keep the wood in the same position as well as to squeeze resin from beneath the wood. I let the epoxy cure so that the bottom was entirely sealed (so there are no leaks during the main pour) and the wood was in place. I removed the clams and other wood.

Main Pour

It was time for the main pour. I heated up the containers with the resin so that they would be les viscous. This will help reduce the number of bubbles trapped in the resin when it cures. This is very important throughout the whole table making process because you can ruin a table by having too many bubbles in the resin once it cures. It is more critical when you do translucent projects, but should always be avioded as good practice. This was why I completely sealed the wood before the pour. This was so that there was no chance of air bubbles escaping from the wood and infiltrating the resin. I made sure to san down all of the cured resin before the main pour in order to provide a mechanical bond between the previously poured resin and the soon to be poured resin.

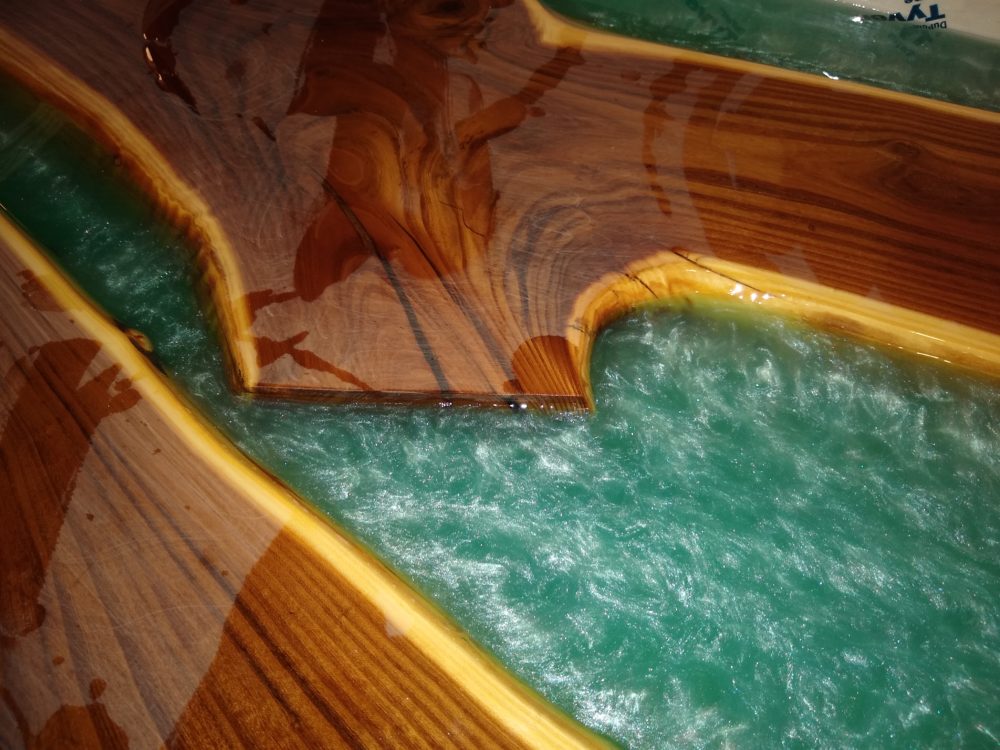

After the resin was heated up, I mixed the entire amount that I thought I need. I calcuated this useing an online calculator that converted volume in inches to Liters. I mixed up about 4.5 liters, carefully paying attention to not creating many bubbles in the resin. When mixing resin you always mix first in one container and then pour it into another container to mix that way you eliminate the chance of any unmixed resin. If you leave unmixed resin in your table, then parts will never harden and your table could be ruined. I split the resin into two in order to make the blue/green translucent part and the purple/white part to pour in after. In the first picture above and to the left you see when I poured in the transluscent part, but had not poured in the other.

At this point I realized that I did not mix enough epoxy for the table. I used about half of the epoxy I mixed and only filled up the talbe about a quarter of the way up. I still had extra so I mixed more and finished pouring the translucent part and then added the purple/white afterwards in order to look like oceans. I ran out of epoxy and was not able to fill it up to the top of the wood. Initially I was really bummed about this, but quickly realized it actually looked more like an ocean meeting land becuase the land (or wood) sits above the water (or resin).

Next Steps

I ordered more resin and sealed certain portions of the table that became unsealed when the resin cured and moved. Once this dries, I will sand the top of the wood, clean the entire surface ensuring that no dust particles are left behind. It is critical in this process of pouring epoxy resin to ensure that you have a dustfree environment, or make it as dust free as possible. If dust lands in your resin (and it will if you are not careful or dont cover it) it will stay there forever. It also looks bad. So just try to aviod that at all costs.

Once the resin cures, I will take the table out of the mold and take it to a friends house in order to use a table saw and router to clean up the edges. The table will look so much cleaner and will be ready for the final coats of epoxy. I will do 2-3 seal coats and finish it off with one final flood coat over the whole table that will dripp off of the edges and give the table a nice finish. After this, The only thing left will be to add the legs.

2 Comments. Leave new

George-

Your project is looking great. I’m glad that you were able to complete it given the circumstances. Have you thought much about your plans for the legs? While the table top looks great, the legs could make or break the aesthetic. Overall very cool project and I look forward to seeing the final product.

Hi George! I am working on a wood resin table as well! The prep you have done is much more well put together than mine. I even had an issue where the resin cracked because I let it cure outside. Good work on taking the proper precautions and keep it up! Excited to see the final product.