Constraint 1: Design Aesthetic

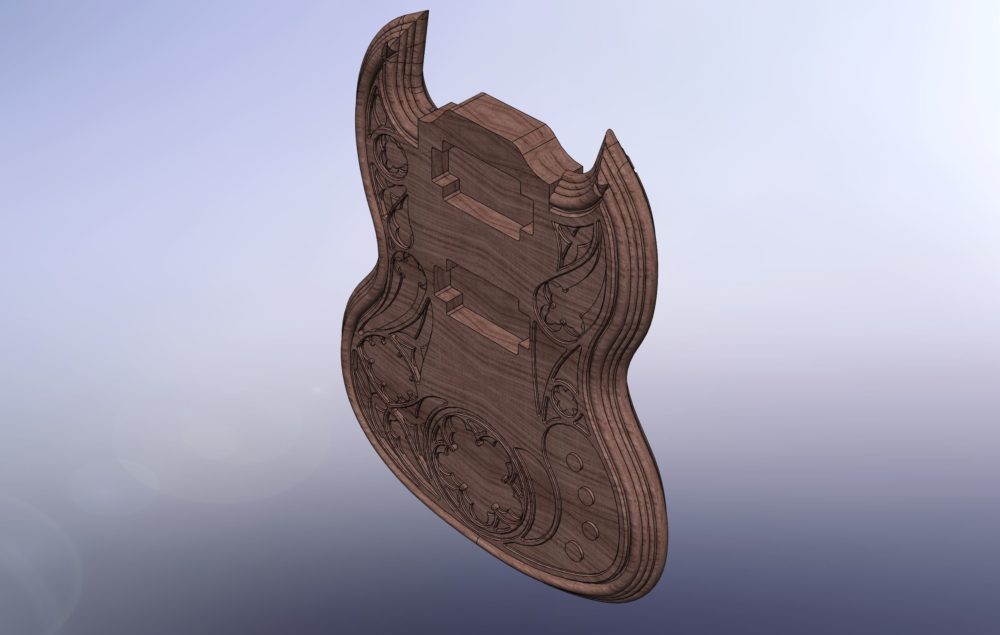

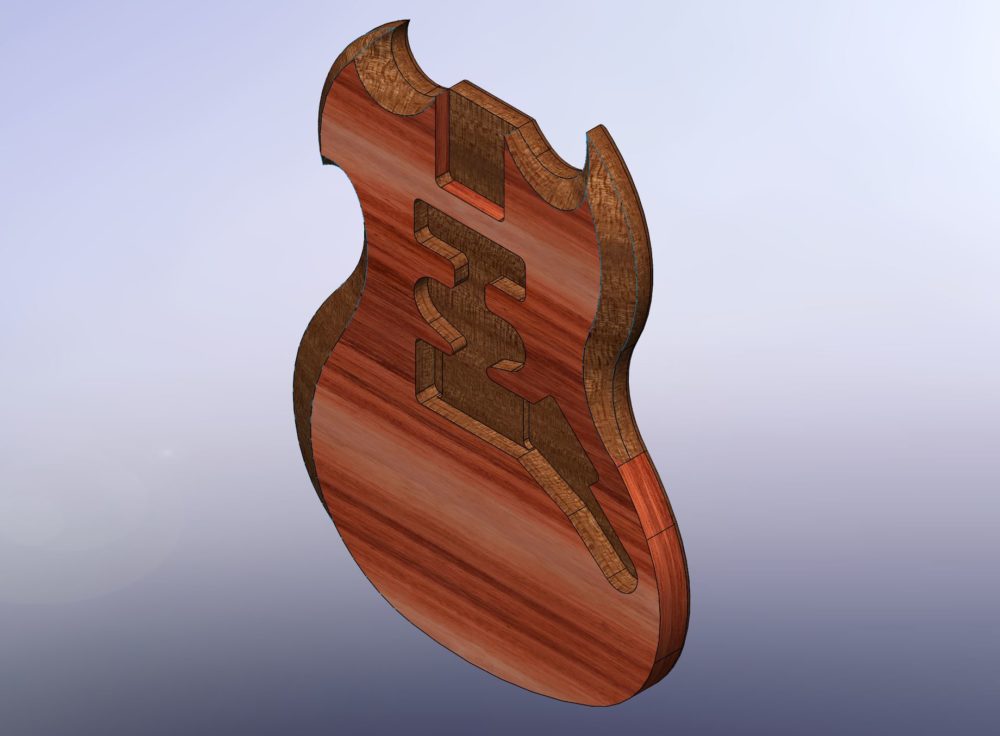

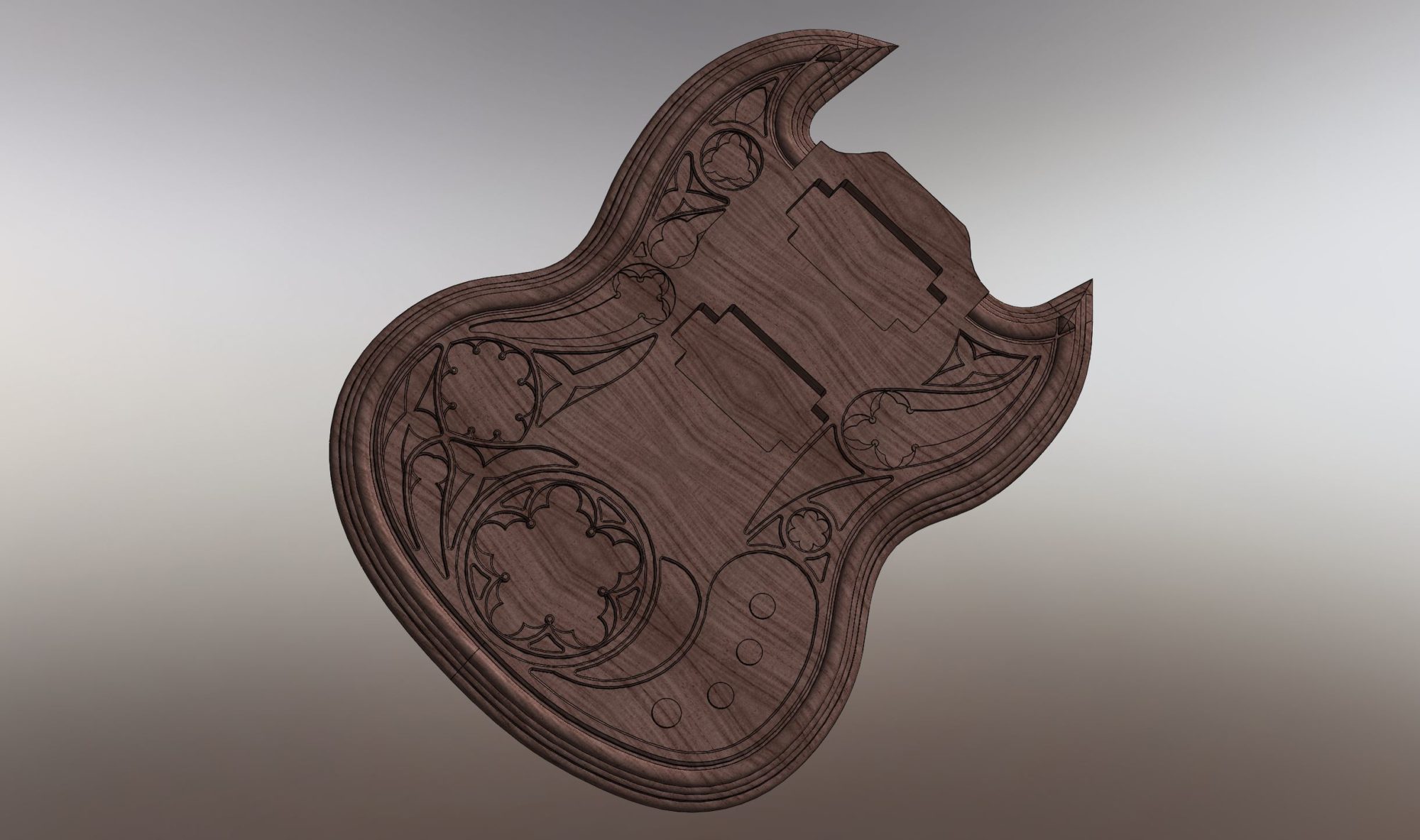

Building off of last week, the original intention was to have a streamline and matte black aesthetic combination or a Dia de Los Muertos type electrical guitar design. But the aesthetic, for the most part, will depend on the other constraints in this week’s post namely Materials, Budget/Time and Manufacturing. The other constraint being sound/functionality don’t impact the aesthetic as much but is detailed later in this post. The aesthetic will be last, apart from the design of the guitar. So far, with design of the guitar’s actual shape, a few initial designs have been done in SolidWorks as shown below. If I were to have a streamline/matte black aesthetic, I would need to obtain some sort of polymer finish, whether it be polyester or lacquer, which I’m not sure I can, but we will see.

Figure 1: Gotisk-Style Guitar (Isometric)

Figure 2: Electrical Guitar with very nice wood aesthetic (Isometric), different shape/design than figure 1.

Constraint 2: Material

The material will be a major constraint as I’ll have to find a electrical guitar hardwood that I am happy with (refer to figure 2), there are many hardwoods ranging from $25.00 to $190.00 (For example, http://guitarwoodexperts.com/electric-guitar-wood/). This directly relates to the next contraint, being budget/time. I could also utilize the site that I used to obtain my Upcycle project material, at RepurposedMATERIALS, and see what type of woods they have that I could possibly use.

Constraint 3: Budget/Time

The cost for the hardwood material will range as stated in the aforementioned section. In addition to the hardwood, all the other components that make up an electrical guitar can further costs, being: the headstock, the machine heads, string guides, the neck, fredboard, frets, and so on. I plan to use around $100 in total, but I might increase this amount if design and progress of the guitar is better than I imagined, as there are always additional aesthetics and construction configurations that define different electrical guitars. There aren’t many weeks left until project completion, so I will have to budget the time and get my materials and start construction early, in order to get to the main part of the project, bringing about a functional aesthetic.

Constraint 4: Functionality/Sound

Given the time, the main function of the guitar, being the sound it produces, is subject to change. Since it is an electrical guitar, tuning and the shape of the guitar doesn’t matter so much as the sound is being produced electronically. As long as it is producing a sound electronically, It will suffice for the scope of this project.

Figure 3. Lots of components that can improve an electrical guitar’s overall construction, all of these will not be included, as this is a representation to an electrical guitar with all possible components (Source: https://en.wikipedia.org/wiki/Electric_guitar#/media/File:Electric_Guitar_(Superstrat_based_on_ESP_KH_-_vertical)_-_with_hint_lines_and_numbers.png)

Constraint 5: Manufacturing

I intend to work closely with the woodworking lead at the Idea Forge, or cut the body with the CNC machines in ITLL with the SolidWorks CAD that I have, thus far. If either of these options are not plausible, I will look to reuse and improve a guitar body. The manufacturing of the guitar will heavily influence every other constraint mentioned above, so it will be the first constraint that I will look more into, moving forward.

1 Comment. Leave new

Will, I wish these were the extend of your constraints for this project–I know we all got hit with a lot more that we expected. Im curious to see what happened with out having access to the Idea Forge. It could always be created through some kind of CAD software if you have that ability!