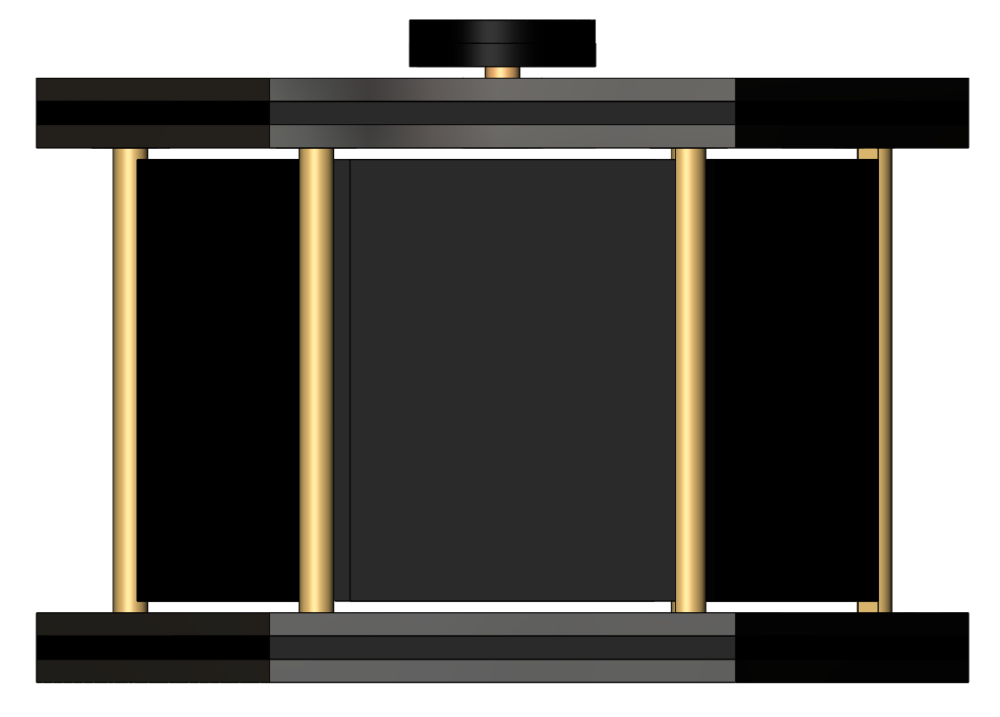

All materials for my upcycle project have been selected. I will be utilizing scrap quarter inch black acrylic for the majority of the construction. I have additionally found some scrap wooden rods with enough length to cut 12 six inch pieces. This is just under double what is required. Below is the CAD model I will utilize to laser cut all of the acrylic pieces.

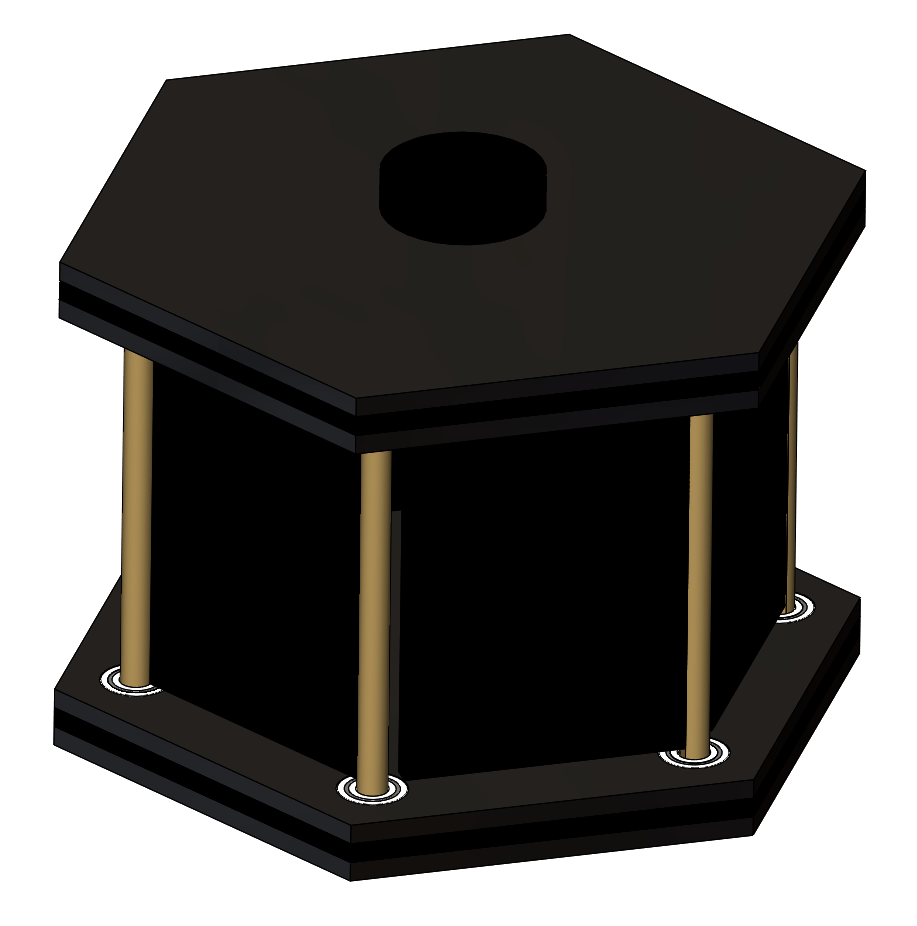

The top cylinder acts as the dial to open each face. The top and bottom plates are composed of 3 layers of acrylic. This accounts for plenty of space for the bearings, which are just over a quarter inch. Here as another view of the CAD assembly:

The bottom and top plates each hold ball bearings to allow the wooden rods to rotate freely. The wooden rods (7) have been cut to length, including a smaller one to support the dial. Additionally, 20 cheap ball bearing have been purchased. I have prototyped a few versions of the gears (which will also be acrylic), because of the specific design constraints, the gears must be designed from scratch. While my first attempt was not successful, my second attempt will likely be suitable for the final product.

6 Comments. Leave new

Jackson this looks great. Is your acrylic going to be black? It gives a very sleek look if so! I will be interested to see how all of the corners end up looking. Whenever I have tried to constrain two pieces of acrylic together it ends up drying so that you can see the glue. It will be very interesting to see what you manage to do to avoid this or if the color will hide it.

Jamie, I agree that this is a difficult problem to solve. If there is any additional glue I plan on sanding it down and repainting the surface with black paint. And yes, I will be utilizing black acrylic.

Jackson,

This is such a neat design and idea. I think its great that you’re going for something pretty challenging for the scope of this project. Im a little confused on how the mechanics of the design work. Do all of the doors open when the dial is turned? how many gears go inside of the holder. Awesome work, and i think assembly should be easy once all of the pieces are cut.

Great question Nate. I agree it is difficult to tell from the images above. I will include an image of the gears in the final report. The dial rotates a large central gear. Each wooden rod is then fixed to six smaller gears. This means all doors open simultaneously, which creates an interesting visual effect.

It sounds like you’ve gotten a fair bit to go still to get from CAD to product. The CAD design looks really interesting. I am interested to see how you’ll get it all to come together. My biggest concern is the time constraint since this is due soon and I know how hard it can be to assemble everything. Try to get everything done soon that way if setbacks occur you’ll have time to fix it.

Hello Kaiya, thanks for the advice! I was able to spend a few hours cutting and assembling on Sunday and finished the final details as of Monday afternoon. While parts of the assembly required some patience, the process wasn’t overly time consuming.