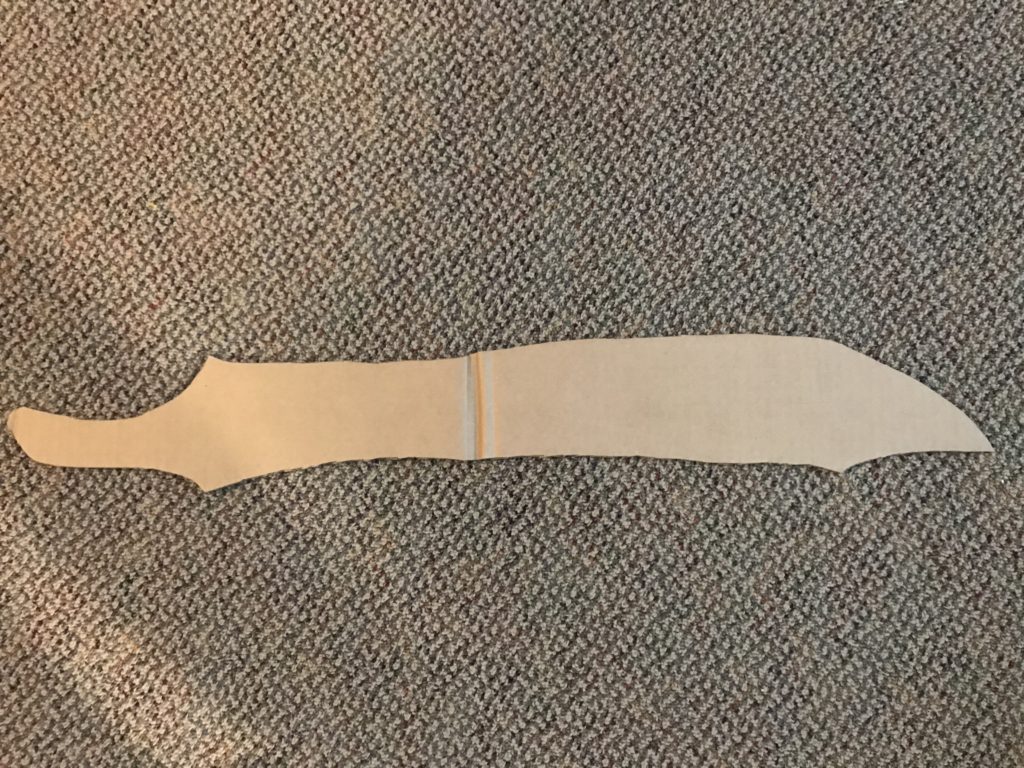

So far I’ve been able to get all the materials I need, but have hit a snag trying to find time to get into the workshop with other things coming into play. I was able to make a cardboard cutout that was an inch too big on the blade but still helped me trace out the places i want to cut for the tip and handle. This should still be useful as the rest is curved parts so I want to the most material as to not undercut those curves. The cardboard outline felt like it was in the right scaling for length a feel. You can see the drawn outline on the wood pieces here:

I’m planning to head in to the wood shop at the end of every day and in between classes. Worst case, I go to BLDG61 on the weekend and do painting over the weekend as well.

4 Comments. Leave new

Hey Joseph this is really coming together well! It has been great to hear that you are making some progress. Make sure to keep in mind the goals you set out at the beginning. I know that you had mentioned some areas of interest like texture, color, and form. Looking forward to seeing the final product.

So glad to see you have bunches of alternative to achieve the your design goal. I not quite sue how thick your wood is but perhaps you can try the laser cut making the cutting process much easier in ITLL if the thickness fits the requirement

Joseph, I noticed you mentioned going to BLDG61. Have you looked at their schedule? They have classes I think you have to take before using their space. I would advise maybe looking into this a little more. The ITLL is also very freed up in the mornings!

Good to hear you have a solid plan of when to actually cut the wood! It seems that once you get time in the wood shop, your project will go smoothly- good luck!