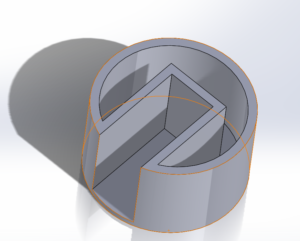

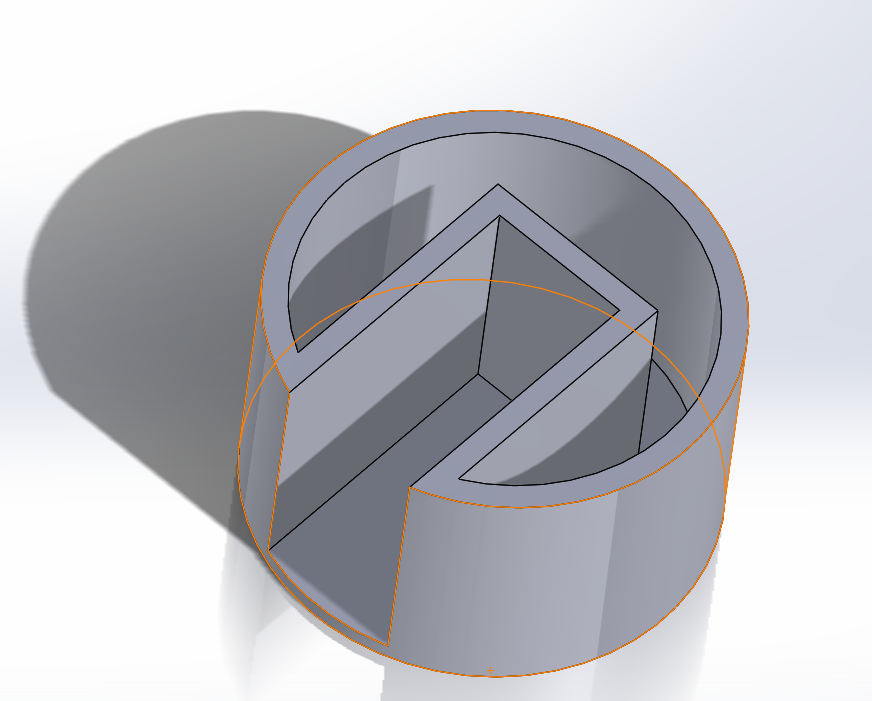

This week I have been focusing on the servo motor to cylinder interface. I designed the housing to be as simple as possible and it can also account for large tolerance issues I will align it with paper as a filling on the sides that need more or less space

Additionally, I picked the inner diameter of the cylinder to be as small as possible and still be able to house the servo motor. To further decrease the diameter of the cylinder I sanded off the mounting slots on the servo as seen in the picture below.

I flipped the order of things in my schedule so although I did some reorganization I am still on track on my schedule.

2 Comments. Leave new

Hey Andres I’m glad you’re on schedule as well. Are you 3D printing the cylinder? I also agree with Joseph on how you take the tolerances for the servo into account.

I’m glad you’re still keeping on track with your schedule. I like how you’ve taken into account large tolerances for the servo to keep from hurting you down the road.