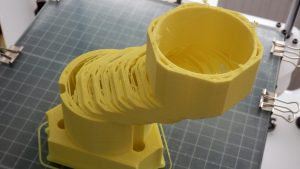

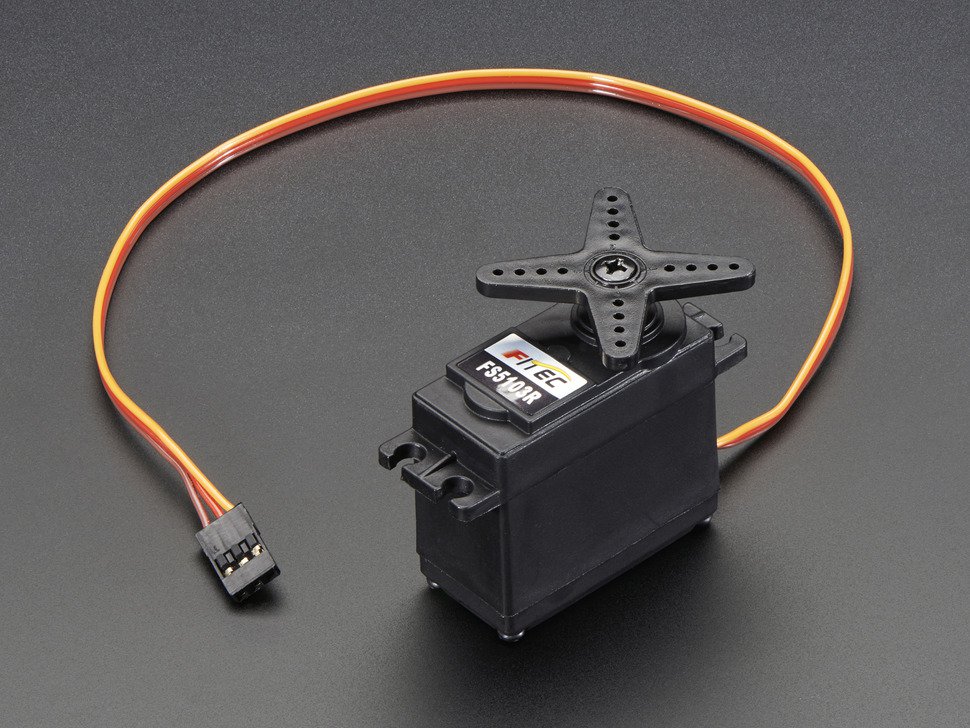

- Manufacturability: Whatever design I wish to pursue has to be manufacturable with CU’s resources either from the ITLL or the Idea Forge. I put this category at number one because even if I have an amazing design in CAD with an exceptionally pleasing aesthetic if I can’t make it I won’t have a project. Although turning a wood block and hollowing out the interior is something I thought about we just don’t have the tools to do it thus I am going to resort to a 3D printed design and I will have to design accordingly.

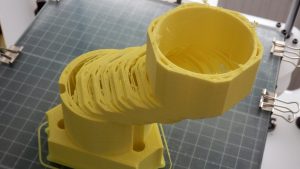

2. Size: I am limited by the build area on the large end and the smallest I can make it is the size of the servo motor has to be able to fit inside. Since movement is a key requirement I need to focus on the servo motor housing and design an aesthetic around it.

3. Aesthetic: Like I mentioned in my previous blog post it has to fit the farm I grew up visiting thus it will have to have a jungle like element.

4. Surface Finish: Over the weekend I listened to a 99% Invisible podcast talking about “Usonia 1” Frank Lloyd Wright’s affordable house. He talks about “Organic Architecture” where nothing can be hidden wood has to look like wood, concrete has to look like concrete etc.. it’s not about using wallpaper. This has got me thinking that I cannot paint the 3D printed surface so I will have to make sure that the surface finish looks professional.

5. Programming :I have just started to play around with my RaspberryPi Zero and I realized that I am not a programming wizard. One of my constraints will be simple programming as I would like to focus on the physical aesthetic of the design.

References: 99% Invisible Usonia Podcast: https://open.spotify.com/episode/4Bmi28Mf8yldVCik09JBSs?si=B_VlptrhSAWXzuiTqqqoGw