Trying to think of final project that had a dynamic aspect took a lot of time for me. I had a lot of projects that I wanted to take on but were all static in nature. On top of that, I gave myself a personal requirement that it had to be functional so that I could use it after the class was over. After brainstorming over these requirements, I began procrastinating with things around my room. I eventually found an old cheap butterfly knife that I had as a kid.

Since butterfly knives are inherently dynamic, I thought this would be a great project to take on. At the time, I had no idea how to do any tricks with them, and I thought it would be a fun hobby to get into as well which would fulfill my personal requirement of being functional and usable after the class was over.

So for the project itself, I wanted to create my own personal knife with a unique look to it. Things like screws and spacers I would just buy since that would just make more sense.

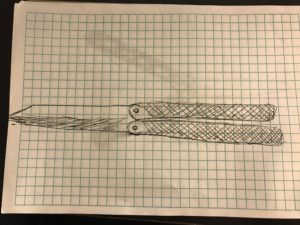

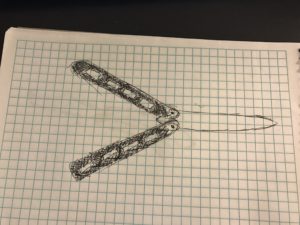

Here are some concept sketches I made early on into my brainstorming:

After researching “high end” butterfly knives, I found the handles are typically made of titanium to keep the handle weight low but still be durable. Aluminum was used on very cheap knives that seem to break relatively easy when dropped, and since I had no idea how to handle one I figured it would be a bad choice to go. Steel can be used, but due to its heavy weight, holes are normally cut out to minimize this factor. Although steel handles still come out to be a little too heavy for effective flipping, the term for performing tricks with butterfly knives. The blades are made of steel.

Source: https://cdn.shopify.com/s/files/1/0867/7400/products/ALPHA_BEAST_3_BRS_-OPEN.jpg?v=1480464399

This BRS butterfly knife is priced at $369.99

For the unique look, I wanted a colorful pop aesthetic. I wanted my handles to have bright contrasting colors. I wanted this aesthetic because I learned it is fairly easy to anodize titanium to achieve a wide range of colors.

Source: http://101bios.com/titanium-color-anodizing.html

The above image are all cylinders of titanium anodized by putting them in special solutions with a certain voltage running through it.

One example I saw that really inspired me but had no idea how to even slightly replicate it was:

Source: https://www.instagram.com/p/BSYtfmqACFN/?taken-by=flipzone999

However, I ran into multiple problems. Firstly, titanium is expensive. It is an expensive material to purchase and it is expensive to machine because of the carbide bit required to even cut into it. I didn’t want to solve this by using the unreliable aluminum so I decided to go with steel. My second problem I quickly learned is that steel cannot achieve the colors titanium can when anodized. To solve this, I found that steel can be heated with a blowtorch that will leave only a surface treatment with a different color. In particular, bronze, blue, and a blueish purpleish color. Lastly, when doing this heat coloring, the steel must be very well polished in order for the color to really stand out.

So my project changed slightly from an anodization process to a heat coloring one. This changed my aesthetic goals as well. Instead on a pop aesthetic it came out to be more of a metal worn/steam punk aesthetic.

I wanted to keep my budget as down low as possible. $150 was the cap I gave myself. Materials I bought were the propane torch which was about $20, sandpaper which was about $5, and parts for a ‘nice’ butterfly knife which came out to be around $90. Everything else I already had. So total costs were about $115 which I’m fairly happy about.

To practice the heat coloring process, I tested it on multiple objects to hone in my technique and timing.

When heated to a threshold temperature, the steel begins to bronze. With more heat applied, it blues then purples. Thicker steels required more time. Edges and corners required less time. If I ever messed up I found that I could just sand down the surface with 500 grit sandpaper and do it all over again.

When heated to a threshold temperature, the steel begins to bronze. With more heat applied, it blues then purples. Thicker steels required more time. Edges and corners required less time. If I ever messed up I found that I could just sand down the surface with 500 grit sandpaper and do it all over again.

So with my handles acquired, I set out to heat up a much thicker material than I had yet to practice with. Overall, I believe it came out very well except not as bright as I had hoped it to be. This is likely due to the finish which wasn’t as polished as I thought it was.

The handles originally started out lighter in color than the blade. It finished with a bronze body and blue highlights over the smaller cutouts.

Lessons learned from this was put a higher quality finish on the metal being worked on, a hotter blowtorch such as one that uses oxygen would drastically speed up the process, and that experimenting/prototyping can save lots of time and money in the long run.

4 Comments. Leave new

Super cool project for sure. Looks pretty tough to manufacture! But that just means that it comes out cooler in the end. Really excited that it came out so well.

Very interesting. This is a unique aesthetic that you don’t see a lot of. The scientific process behind it was eye opening. Do you plan on anodizing other metal items you have other than your knifes?

I am so fascinated by this idea. You did so much experimentation and I commend you for that. The more you experiment, the more you can refine. I love the sleek, subtle neon color aesthetic that was achieved and I believe it contributes a whole new level of quality to your project. I would love to see you experiment with a knife made from Titanium since the colors produced on this material are so dramatic.

Wow this is a really cool project! I like that you did different tests to see the colors you wanted. Could you have done this with a regular pocket knife? Overall, great job!