Why and What next? Reflection on the semester. Compare your original project intent to what you ended up with. How did the public react? What did you learn from your project, and from the class? What will you do next with the project? What do you wish you had done differently? (You can copy some of this to/from the Exit Survey)

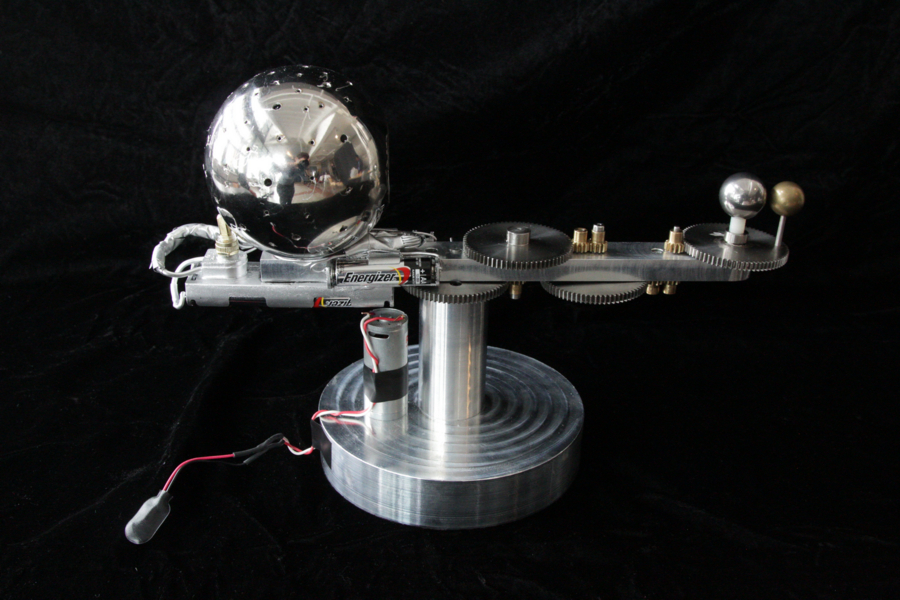

This project turned out pretty close to the way I wanted it to. I accomplished most of my goals in the design and the aesthetic. During expo, lots of people came by to see the project. I was in one of the upper DLC halls away from most of the class. Most people that came by were pretty impressed with the out come of the project. I think that being close to some of the freshman projects definitely helped with their opinions. Seeing as I had to present the project to them most were looking for a poster which I could have done better.

As for what I could have done better. When I was assembling the project I notice that some of my threaded connections came loose after the motor turned the gears. This could have been fixed by using a lefty screw instead of a normal one. Also, some of my machining came back to bite me. This was in some of my press fits with a thread where the thread was slightly off which caused a wobble in the gears. This compounded through many gears and when two gears became out of sink, they froze and caused a glitch in the moon’s rotation. Looking forward, I will try not to rush the machining and pay more attention to the quality of the final product. I think that I was in a rush trying to complete all my parts in time for assembly.

Aside from those issues, I wouldn’t change to much about the final project. I would however try and find a way to make this project plug in to a wall outlet. This would allow for the lights and motor to always be powered and not rely on batteries.

Whats next? Well it will probably be a item on display in my house. I don’t think that I could modify it in a way to connect power with out completely redesigning it.

1 Comment. Leave new

This looks like it came out great! I wish I was able to see it in person; I didn’t realize that there were other projects displayed upstairs, but it’s great seeing these projects posted here. One trick you can use with press-fit parts is that you can machine the smaller piece slightly larger, freeze it, then as it shrinks, it becomes easier to fit into the slot. I’m glad you received a good reaction from the crowd. You probably got a different group of people since you were closer to the other class. Overall, great job!