For my project I decided to make a saxophone out of upcycled materials. I was having a lot of trouble deciding what I wanted to create for this project until I thought back to a recent concert that I had attended. The group Moon Hooch plays live shows incorporating 2 saxophones and a drum kit. In addition they create completely unique sounds by making modifications to their instruments out of upcycled materials. They started as a band playing in the subways stations in New York and the materials they use for the modifications display their roots. Since I grew up playing saxophone in the train stations of New York as well, seeing them inspired me to create something similar.

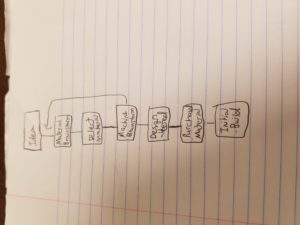

My original idea was to make a wooden saxophone, but I soon came to the realization that manipulating wood to fit the shape and be airtight was not viable. After brainstorming other materials to use, I decided on metal piping for a few reasons. They are already hallow, there are curved connecting pieces that are made to be airtight and the metal would keep the bright sound of the saxophone. My goal was to practice getting the pitches correct with PVC pipe because of how cheap it is and easy to cut, then transfer that over to a metal pipe.

I did a significant amount of research on how to get the pitches correct, and tried that during my first attempt. I planned on using PVC pipe to experiment then, transfer that over to the metal piping. After my first attempt at the saxophone, I realized that trying to use the harmonic series was too complicated and not going to work out. I then tried to match the sizes of the PVC with my saxophone and use the buttons as a reference for drilling the holes.

I ran into a few problems with this. The most limiting, was how far my fingers could reach and still create an airtight seal. Yet after resealing the holes that I could not reach, I was able to get a range of pitches that was a good starting point. At this point I realized that I was not going to be able to transfer this to the metal piping because the material would make the pitch change a significant amount. I then got a 10 foot piece of PVC and was able to create run a trial and error system to work toward my final model.

After a while, I was able to get the pitches calibrated, but because of how far my fingers could reach I was only able to hit a certain range of notes. This project could have been completed into a real instrument if I had more time and a budget for this and definitely something I continue to plan working on in the future.

8 Comments. Leave new

This was a really awesome idea for a project, and it seems like the final product turned out very well! I also decided to try and construct an instrument for my Upcycle Project, and I think the idea of creating something that can be used to make music is a really enjoyable process. Great job!

It was interesting to hear how you traversed the obstacles that you faced throughout the process of developing your design goals. I do think that your musical background paired with technical knowledge helped you to overcome these challenges and come up with creative solutions. I hope that you may try another spin of this design an incorporate the lessons learned and design changes that you discussed after your presentation (locating the holes, etc.). This was a very fun project to see and overall my primary suggestion would have been to spend a few more minutes on your PowerPoint, it was a little bit bare bones. Hopefully we will see you out on Pearl Street tearing it up on your upcycle instruments.

The fact that you were able to make a working saxophone out of PVC pipe blows my mind. You should definitely take it to Pearl Street sometime and rake in the money. It was interesting to hear the challenges you faced in building and playing the instrument. Nicely done!

Good use of materials. The saxophone sounded great which really surprised me. The iteration process sounded grueling but it ultimately paid off it sounds like and the different ways you cut holes really added to your process. The sax was visual similar to an actual one which was nice.

Great use of pvc pipes. It seemed difficult to determine where the holes would go in order to play the correct notes. You did a good job making the pvc pipe look aesthetically pleasing.

I like that you had to try a bunch of different lengths and sizes to find different sound qualities. This project is awesome because you are building something you enjoy to do. Your final design looks awesome and playable. You could even spray paint it to look just like a brassy saxophone. Great job.

Very creative! Super impressed you were able to make an instrument that actually works out of old material. Although it’d be a lot of work, it would be cool to build enough instruments to have a whole band playing on upcycled instruments.

I liked hearing about your design process and your road blocks, especially with your decisions to forego the wood and metal piping. Also, I think you did a great job really trying to make an authentic saxophone with the curves in the holes for your fingers and getting the right pitches. Great job!