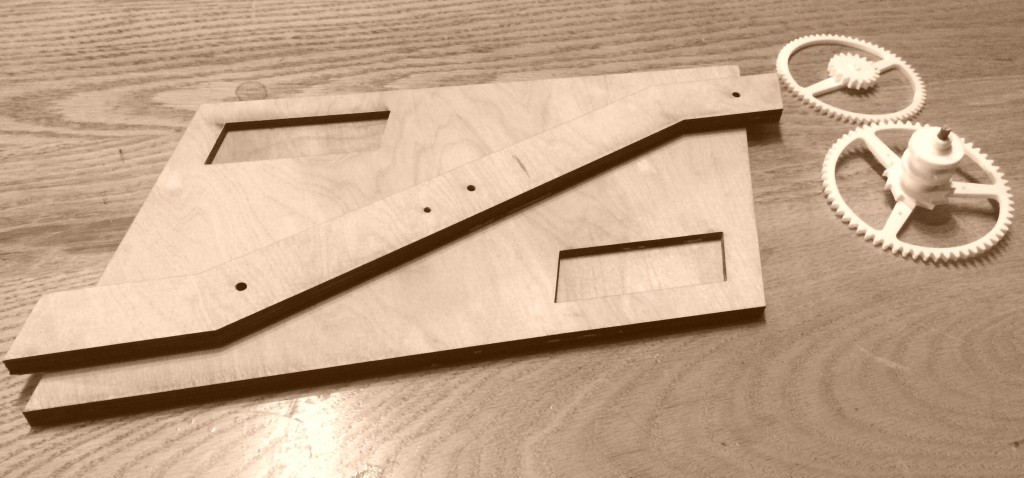

This past week I’ve been busy fabricating my design. The 3D printed parts take a surprisingly long time to print! This is partially because they need high infill for strength and partially since I’m using the “fine” layer setting (0.2mm) for a nicer surface finish. Yesterday finished, cutting all of the wooden parts I need on the BTU lab laser cutter. Despite the nitrogen gas, there was still some burning when cutting the wood. To reduce the appearance of the burn marks I sanded the surface of the wooded sheets with a fine grit sandpaper. I then bonded the wooden layers together with wood glue to create pockets for the bearings. I’ll receive my final shipment of parts from McMaster Carr on Thursday and complete the final assembly this weekend.

1 Comment. Leave new

Hello Nick,

Since these are fairly new for me (e.g. 3D printing and wood work) as I might have mentioned before, reading your post is always interesting and informative for me 🙂

I wish of you had more pics of what your products look like so far, but I guess we’ll be able to see final product soon. I don’t any critique for your design honestly and I’m also looking forward to see your final project since I’ve been following since the beginning ^^

Best of luck!