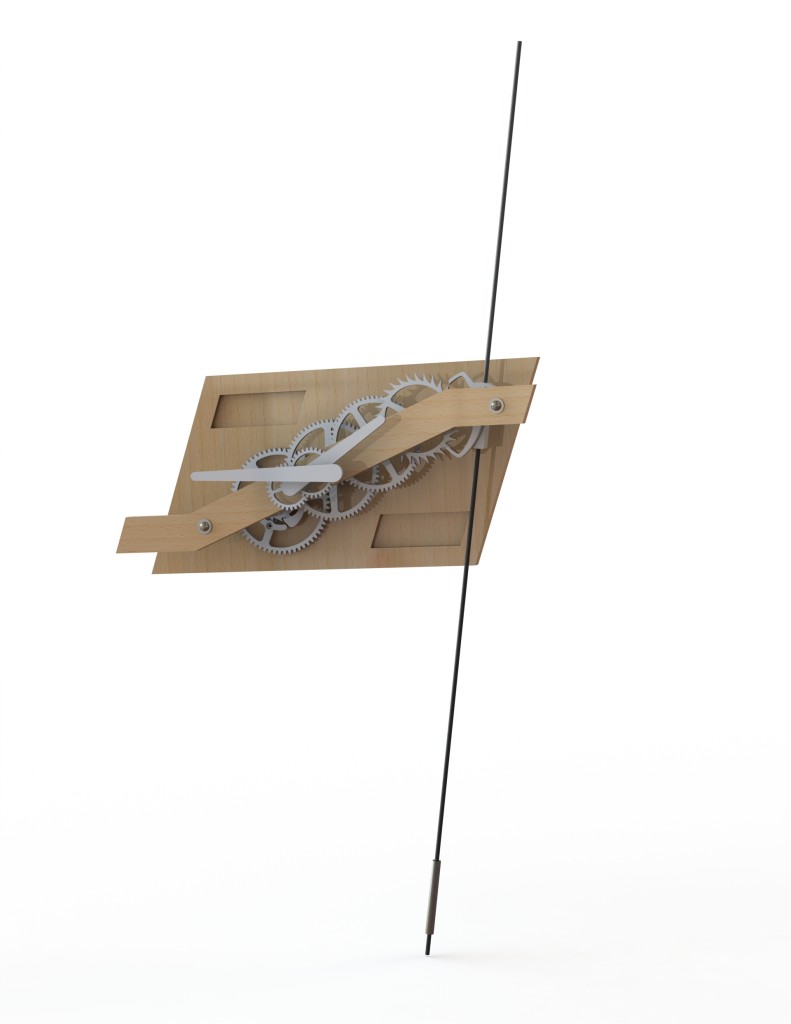

This week I completed my project design – the clock consists of 4 laser cut sheets of plywood that are held a fixed distance from each other by two bolts and spacers. The gearing is suspended between two plywood sheets and held in place by small bearings. The for simplicity, the gears will be 3-d printed out of PLA plastic and glued together. Overall, I tried to design the clock so it would be easy to fabricate and assemble. However, one area of uncertainty is in the 3D printed parts. I’m unsure what tolerances will be acceptable for the gearing escapement mechanism to work properly. Fortunately, I should be able to alter my design quickly if needed or file down parts if they’re too large. I’m looking forward to having the clock fully running!

Search for content or authors

This Year’s Students

-

Abby Rindfuss

-

Adam Hosburgh

-

Airyl Dayrit

-

Akash Karoshi

-

Alex Jessop

-

Xander Johnson

Allister James Sequeira

-

Annie Cai

-

Andrew Chamberlain

Anjali Shadija

-

Anthony Makuch

Andrea Marks

-

Anthony Papaianache

-

Andrew Perper

-

Andrew Widner

-

Ariana Ramirez

-

Arjun Ramachandran

-

Arden Villanueva

-

Ayesha Rawal

-

Ben Erickson

-

Ben Harming

-

Ben Haley

-

Brian Ahn

-

Bryce Johnson

-

Bryan Moreno Najera

Brenton Yu

-

Cason Lane

-

Cecelia Shoenfeld

-

Chris Adami-Sampson

-

Chrisanna Bertuccio

-

Witt Young

-

Claire Markus

-

Clemens Pacher-Theinburg

-

Cooper Kramis

-

Cole Romig

-

Cole Sites

-

Cort Sommer

-

Daniel Carranza-Valenzuela

-

DawnMonique Cantu

-

Seth Strayer

-

Danny Vesselovskii

-

David Whisnant

-

Delos Ashcraft

Dev Mahajan

-

Ellyse Jensen

-

Elise Johnson

-

Eli Skelly

-

Eric Fiechtner

-

Evan McCleary

Francine Palmos

-

Garrett Jimenez

-

Garrison Nazare

Rauba, Grady

Reilly, Greg

-

Grant Thompson

-

Isaiah Straubel

-

Jamie Blanco

-

Jacob Foley

-

Jack Franz

-

Jacob Krajnik

-

James Overberg

Jackie Padilla

-

Jaks Praeger

-

Jax Whitham

-

Jessica Vo

-

Joe Yoder

-

Jules Fischer-White

-

Kalin Myers

-

Keith Hemenway

-

Kyle Chinn

-

Lia Cucuzzella

-

Lindsey Trussell

-

Luke Gordon

-

Matt Bloomfield

-

Matthew Cumpton

-

Mateo Esteve

Matt Sherman

-

Max Van Cleave

-

Max Williams

-

Mila Bergmann-Ruzicka

-

Min Than

-

Mia Winstead

-

Nile Brown

-

Nita Byati

-

Nick Rios

Patrick Hetlage

-

Pisay Suzuki

-

Robert Forstbauer

-

Rystan Qualls

-

Sam Nicastro

-

Scott Ehrlich

-

Seth Dry

-

Sean Ostrander

Senayt Wolde

Shubham Dhumal

-

Shreya Pradeep Sekar

-

Sofia Fernandez

-

Sylvia Robles

-

Tay Cummins

-

Tanmay Mhatre

-

Taylor Wittwer

Thomas Brentano

-

Tyler L'hotta

-

Tyler Lloyd

-

Zoe Cooper

-

Jean Hertzberg

2 Comments. Leave new

I like the look of the design. I wonder if the finish on the printed parts will be an issue, especially where the gear teeth contact each other. You might want to sand them anyways.

Also, if you decide to paint the wood, I would choose a color that contrasts the color of the gears.

What a great news!

wish we had more views of the design, maybe next post?

are thinking of using color at all?

Also, I wish I could give more advice about the 3D printing, but I’ve never work in depth with such printer. So, I’m looking forward to see your results and trouble shooting process!