To see previous updates go here

After waiting a week to get some more hardener and epoxy resin, it finally came today. Last weekend, I bought a set of trucks, bearings and wheels so I only had to finish the deck for a working skateboard.

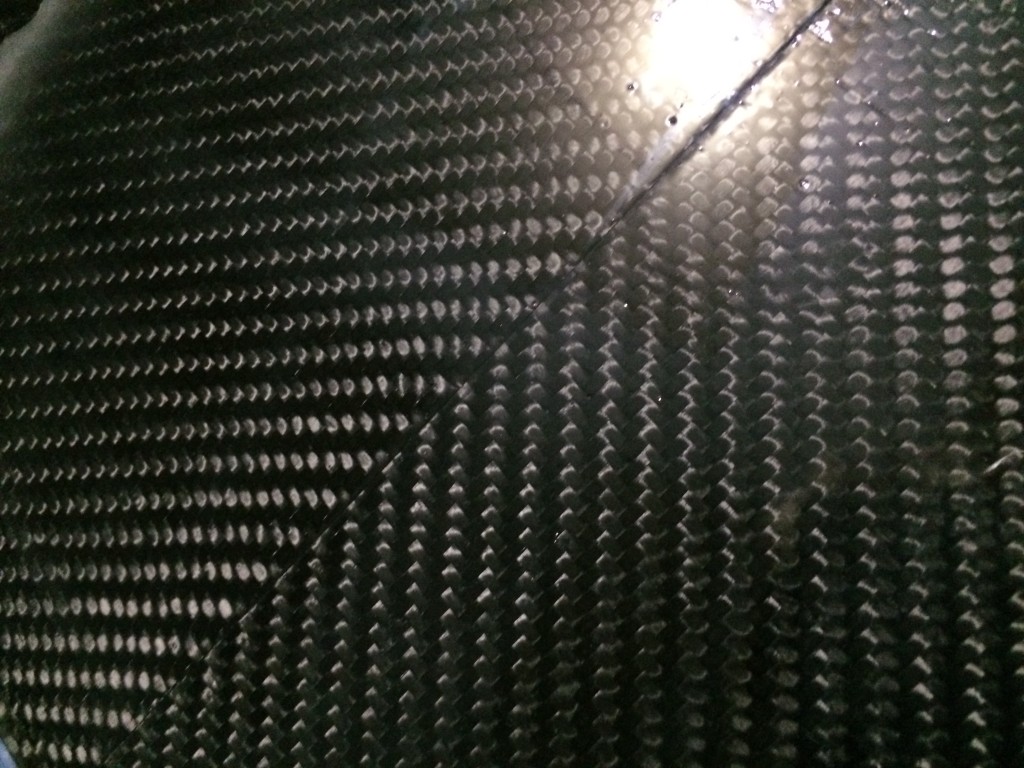

I already had one side of the deck laid in carbon fiber so I essentially did the same process on what would be the bottom of the board. I laid down carbon fiber with the weave oriented different directions. This side has 3 layers of 2×2 twill and one layer of plain weave.

I am planning on also having an interesting carbon fiber design on the top of the board. Taking inspiration from the nose of a Pagani Zonda (many other super cars have carbon fiber like this now) I am going to create a “V” shape with the weave pointing forward. At this point, I’ve done a practice piece of carbon. I’ve even wet sanded it and finished it with a layer of epoxy.

Pagani Carbon Nose:

Top of my longboard detail:

1 Comment. Leave new

I’ve always been interested in carbon fiber construction, I’ve watched some YouTube videos on how to make them and it’s such a time consuming process and requires a lot of materials. How are you joining the two halves together or has it been just one working piece so far – it’s kind of hard to tell. Are you going to be applying some sort of clear coat or resin layer to achieve the glossiness? Looks great, you’ve got the hard part out of the way it seems!