Here are updates on my project since my design review (link). What may be most helpful is my list of refined questions and things to focus on.

- I gained a lot of insight when I finally talked with Charles who owns and runs Boulder Glass (he is a great guy and really giving of his time).

- Glass pane: ¼” tempered

- EXTREMELY strong in the middle, and yes the edges are still very sensitive so the frame enclosing the edges is essential.

- The edges are “polished”/rounded as a part of the tempering process which adds some protection to them.

- Glue is not necessary! The edges just need to be encased so that they are protected from anything. With the glass in a frame, you could safely stand in the middle of the pane.

- Weight: ~3lbs/sqft

- 3’x6′ = 18sft = 54lbs

- 3’x5′ = 15sft = 45lbs

- Charles heavily suggested the framing to resemble a picture frame

- Nothing to worry about for us in regards to distortion – it would only be a problem from extreme viewing angles which isn’t a problem for boards on the wall.

- Cost per 3’x6’x ¼” pane?

- Around $210

- What is the lead time for ordered panels?

- ~24 hours

- Local delivery is possible – extra ~$30

- Glass pane: ¼” tempered

2. On Thursday last week, I talked with Josh Colyer in the Idea Forge. Josh specifically runs the Maker Space in the Idea Forge and has a lot of experience with wood working.

- A great design option that he made me aware of is the “french cleat”. This design is a specific way of hanging things on walls without any fasteners showing. The pictures below show this idea and are from a sign in the Idea Forge.

2. After showing me the above framing option, Josh also recommended that I make a trip to the local store, Mike’s Camera. His recommendation was based on the custom framework department that Mike’s Camera has, and their experience with hanging-projects related to this.

3. Josh also helped to point out that wood framing runs the increased risk of getting damaged and/or looking scratched in a shorter time period. Therefore, I have decided to include some aspect of metal framing into the design.

i. Either the entire frame will become metal (expensive) or a metal trim will be added to a wooden frame.

ii. How will metal affect the dynamic aspect of this project? Will it help or hinder with aesthetic attachments?

3. Initial meeting with the hall director in my hall – Molly

- My goals for this meeting

- Make sure that project seems reasonable

- Set up a future meeting as soon as possible with facilities to understand any additional or unforeseen requirements.

- Overall, Molly liked the project idea and couldn’t think of any reasons why it wouldn’t be allowed.

- I passed on as much info as I could to Molly and am now waiting to hear back about our next meeting with facilities personnel.

4. Mike’s Camera

- Ultimately not very helpful for our structural questions, but it was great to see the options for extruded aluminum framing material that exist. These are some pictures that I took in their store:

5. McGuckin Hardware!

- This was an amazing place to finally stop by; now I am ready for prototyping!

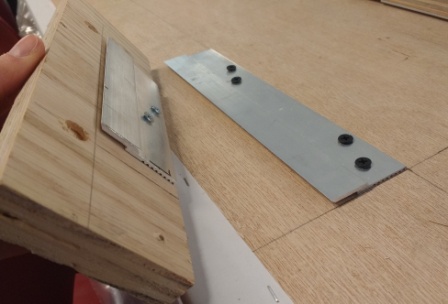

- The best part is that I learned about a neat piece of hardware to help with wall hanging: a keyway plate. I think that these plates will work great for hanging a pre-assembled frame onto the wall (as long as measurements and holes are accurate). Here is a picture:

3. Here is the other hardware that I got at McGuckins to prototype with:

i. Snaptoggles

ii. Tee nuts (right side of picture below) & Wood inserts (left side):

iii. Lumber

4. In this store it was also helpful to see some mirror-mounting plates, j-channel strips, and metal bars that they have.

6. Research

- Writing surface: Alternatives to glass in order to save on weight and possibly thickness?

- Painted steel or aluminum

- Easily cleaned but get scratched

- Laminate

- scratch-resistant and stain-resistant

- Glass

- scratch-resistant and stain-resistant

- Custom Design will show through!!

- Porcelain

- scratch-resistant and stain-resistant

- sounds like great quality, but at highest cost

- Melamine

- Easily cleaned but get scratched

- Least expensive/most common

- Painted steel or aluminum

New/Refined QUESTIONS:

- Frame:

- Slotted Frame or picture frame?

- Slotted more robust because each side is a solid piece? Of course, a router could be used to turn side pieces into picture frame style and remain as solid pieces…

- Would a picture frame style frame be easier to assemble the glass into?

- Wooden frame with metal trim, or does whole frame need to be metal (more expensive)?

- Ex: NielsenBainbridge framing – see figures above under Mike’s Camera

- If wood is covered by metal trim, does its mating config matter (angled corners)?

- Manufacture out of big panels, or assemble sides together?

- Slotted Frame or picture frame?

- How will metal affect the dynamic aspect of this project? Will it help or hinder with aesthetic attachments?

- Mounting:

- Keyway plates OR French cleats?

- Security requirements?

- Does GLASS need to be used??

- Whatever material is used, will a small amount of glue be useful in the slot?

- Aesthetics:

- What is Scot’s idea for customizable aspect? – will wood inserts work?

- Image printed on paper or engraved in wood?

- Paper will be thinner…

- Marker/Eraser holder?…

- Create hidden magnetic pocket somewhere (in frame)?

- 3D-print marker holders (to match aesthetic…) such that marker snaps into place.

6 Comments. Leave new

[…] are updates on my project since my big update last time (link). The important update is that I was able to finish my first prototype before spring […]

This is a really awesome project idea. It sounds like you have thought out a lot of the different steps. I don’t think that glass is absolutely necessary, although it would make the project really interesting and beautiful. Excellent progress so far. It definitely can be good to talk to people and get a sense of what you know, and what you don’t know. Then you can identify different problems that can arise later.

It looks like you’re making great progress. I would go with a metal frame personally since I think metal gives glass a better look especially since this glass writing board seems unique and almost futuristic to me. Cost is a problem though and to me woodworking is a lot easier but metal could also provide a sturdy frame and I’m sure Greg would have some good ideas how to secure enough of the edges so that don’t shatter or chip.

This is great progress Matt. It’s great that you got hold of Boulder glass and it’s even better that you talked with Charles (this is a good opportunity to talk to someone who knows more about glass). The questions you have about moving forward with your project prove that you have been thinking a lot the project. I think you have a better idea of the challenges by now specially that you started building the board.

I agree with Gardner regarding acrylic vs. glass. I also think wood engraving would look much better than just printed paper, although would also be much more difficult. The mounting cleat thing is a great idea though, I may actually end up using that for my project; I’ll need to wall mount as well. Those are pretty structurally sound in my experience, which will be good for you (and me…) in mounting a potentially heavy piece.

I really like the see through boards in the Forge, so it’s exciting to see someone replicating them. The one’s in the Idea Forge aren’t made from glass however because they were having problems with them shattering whenever the brackets would attach to them or if they hit a bump while rolling around, I believe. To answer your question if glass should even be used: acrylic would be much easier. If you can make glass work though, It would be a higher quality product than the one’s in the Idea Forge so I think it would be worth figuring out.