First off the Wine Knife is taking shape quite well, however with all design this project has a few constraints which I will detail below.

Having spent a fair amount of time this week on Solidworks I have identified the first major constraint, size. The artifact is quite small, measuring, hopefully, just 5.5 X .8 X 1.1 inches, so fitting the screw, tooth, bottle opener, spring, backing, foil cutter and handle material into such a small package has become the biggest issue one which I hope is now currently solved.

Material selection is the next major obstacle, wanting to use primarily 6061 aluminum requires minimum thicknesses to maintain rigidity, the spring and fastener material (studs and bolts) are comprised of steel, and the handle material is still not chosen or ordered.

Hardware has become an issue as the small size of the pieces combined with the overall width is making pivots difficult to find. The only solution so far is to combine two pivots per joint which would be tricky. I am still contemplating how to solve this.

Perfection, I cannot help but want angles to match, parallel lines to be actually parallel, sizes to fit the constraint. I would continue to design this for another year until it met my stringent expectations, however I came to realize, after scrapping another 6 hour design, that some parts and pieces are what they are and to make the design work, within this time frame, I would have to bend my thoughts on perfection. Surprisingly the details which I let slide are actually improving the overall design, and adding ease to the function.

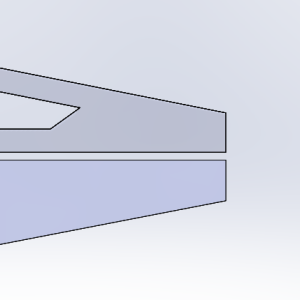

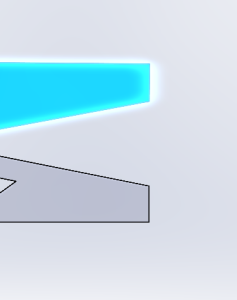

Stability would be my last constraint, as the design relies on a double hinge making everything align in both the open and closed positions while maintaining full functionality has become an issue, any ideas to locating and locking odd ended handles in place? Need to lock these

handles seen below:

4 Comments. Leave new

How do you add more than one image per post to blogspot?

The perfection constraint is something I deal with on a regular basis too. For that reason, I try to keep a list of critical requirements handy throughout any project. It helps me focus on the big picture rather than pine over details that may require immense amounts of work but don’t result in much overall progress.

I’m really glad that the design iteration is working for you! I’m a bit worried that if your aluminum piece gets too thin it might bend while you are using it. I doubt you are going aluminum can thin but just something you might want to keep an eye on and maybe test the strength of the piece.

It sounds like relaxing your perfection constraint has worked out for the best. I’m not sure how small of pivots you are looking for but it is common to use rivets as a bushing for pivoting parts in knives (especially cheap balisongs) or corkscrews. I don’t quite understand what you are trying to show in your images but would be happy to think about it if you clarify.