For my final project, I’m going to build an expanding table. As much as I’d like to build an expanding table with an intricate system, I’m going to keep it simple and completely manual. Again, I’m going to play on the aesthetic of mixing organic and inorganic materials and shapes that I explored a little with my first project.

Being very interested in race cars, I would like to build some of my own parts for a race car some day. I’ve long been interested in carbon fiber and have done a few small projects with it in the past as well. I’m going to attempt to replicate a splitter design with my table to get some more experience with functional carbon fiber parts. A splitter is a part that protrudes from the lower front of a race car. It’s essentially a flat piece that guides air over and around the sides of a car rather than underneath, thus helping create downforce (which is good for cornering). A lot of my build technique will match this project thread: http://speed.academy/s2000-custom-splitter-build-how-to-part-2/2/

Although it will appear that I am making a race car splitter, I will be making a table. At first sight, I’d like my table to look high quality and durable. An aura of class and sophistication would also fit the goal. I’d like to be able to use this artifact for many years in the future, so it will be a functional table. It will be able to expand in the middle where a leaf can be manually inserted. The functional goal of this table is to simply work (and last for years), and be durable. It should be able to hold the weight of someone sitting on it easily and hopefully not wear very easily.

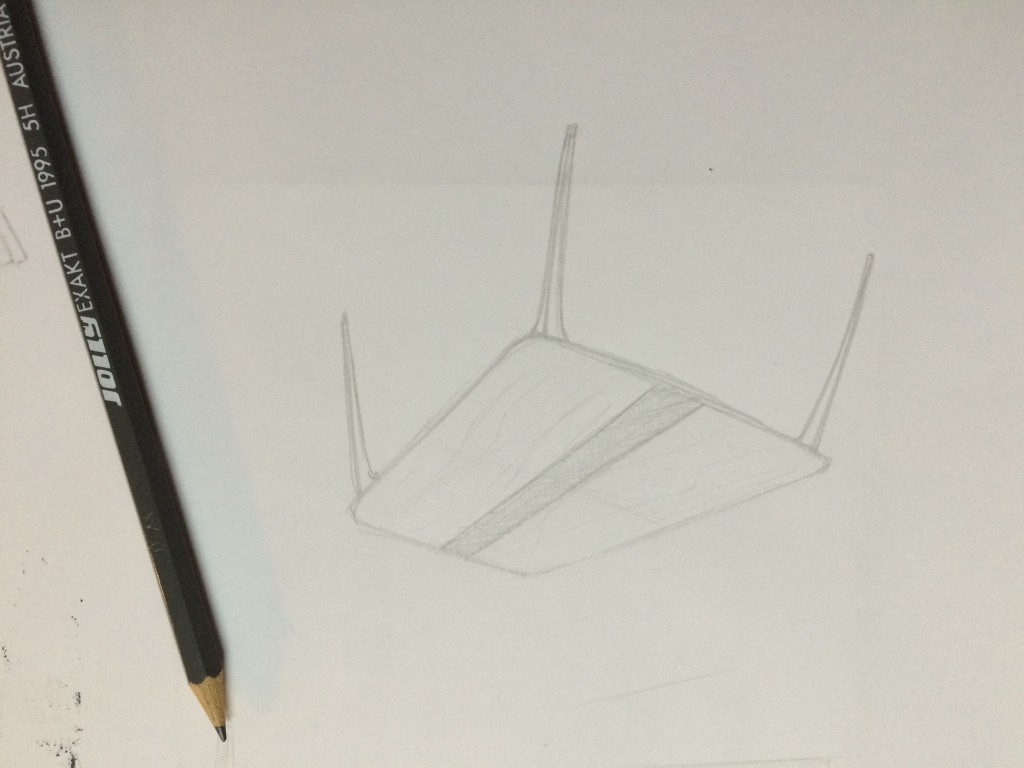

The aesthetic goals are to look contemporary, but still very natural and approachable. If my aesthetic goal is achieved, this table shouldn’t be intimidating, it should want to be used and very straight forward. In my concept sketches, I have a simple, rectangular table that has a strip of visible carbon fiber running down the middle. To either side of the strip will be a hardwood veneer. The whole table might have a matte varnish on it as well.

Some of my inspiration came from race car parts like the one in the project thread attached above. Parts like this are generally very high quality and are built to withstand a lot of abuse. My other inspiration is from normal furniture that encompasses my aesthetic.

The most critical part of this table is probably the expanding mechanism I plan to build. I hope to use an aluminum tube that will act as a slide mechanism for the two sides of the table to freely slide together and apart. This part isn’t too difficult, it should only require some very easy machine work.

This table might cost quite a bit with the use of carbon fiber. The foam core won’t be expensive, but the resin and hardener and body fillers add up quickly. I will use some unidirectional carbon fiber that was given to me for free as well as some 2×2 twill carbon that I will have to purchase. The aluminum for the legs and polishing compounds will also be costly. I imagine I won’t spend more than $300 for the entire table. This weekend I will purchase the foam and a lot of the liquids, compounds, resins etc. Over the next few weeks, I’m confident that I can make the table top and slide mechanism. I hope to have the aluminum and legs purchased by spring break. Hopefully everything can be assembled by the second week in April so that I can spend the last two weeks working out any last minute fixes.

Here’s a link to my presentation video!

https://www.youtube.com/watch?v=mOFC-BSZy_g

A note: I would add more photos of concept sketches and inspirations, but the site will not accept my pictures. It took more than 10 tries to upload the one picture in this post!

5 Comments. Leave new

I like where you’ve arrived; most of my concerns are resolved with this design, in terms of mechanical complexity and function. I trust you know what you’re doing (you seem like you do)…this stuff isn’t easy to lay. But I think you’re doing it right in using uniaxial to build up the support a little cheaper and then use the trill pattern for the outside aesthetic. I don’t remember if you were going to lay up the whole table in carbon and then cover it with the wood paneling or do different sections, but I’m sure you know there’s no need to put the expensive stuff under the wood. Dr. Hertzberg brought up another good point, that interface (where the two halves come together) is definitely going to be the critical point in maintaining the look.

This is an awesome idea. It is going to have a very unique look. I am interested to see how your table expands and the finish on your table. I do not think that I have seem tables made of carbon fiber before. I also admire your sketch art that you showed on your presentation, the detail is amazing.

I really liked the use of carbon fiber as an accent in the center of the table. I’m looking forward to hearing more about construction process.

Carbon fiber is new, but definitely a unique way to get the modern mixed with natural materials aesthetic. I think I like that better than anything we’d thought of, honestly.

Sounds like a perfectly table for car guys! If you clear coat the carbon fiber it would be so cool!