Inspiration

This exploration into an artistic creation has been very different than my usual design loop. I started with a problem of “make something”, which in itself is a much different jumping off point than I’m used to. What’s more, even once I figured out what I was going to try to make, I didn’t really know how it was going to be done, I just started. As I put certain parts together, others were discovered and eventually I had the entire picture in my head. This worked well in the sense of incorporating a timeline, where I was allowing myself to fast track the build of my piece, but in the end I finished with a project that isn’t fully cohesive. It could be argued that “lack of cohesiveness”, or “disorder” itself is an aesthetic, but I’ll be honest, it wasn’t the one I set out to make. All in all, I would feel guilty calling this a complete success. Even so, the product is kind of fun and the idea can be really easily carried forward.

My idea started after seeing the head valve lying deep within the storage room of the Mechanical Engineering department. Weirdly, my first thought was, “that’s kind of cute” (weird because I was thinking that about a valve, a completely inanimate object). I realized pretty quickly that maybe an aesthetic of cute, specifically cute everyday objects is an interesting feeling. I decided to make a puppy out of old industrial parts, trying to combine that feeling with an aesthetic commonly explored in our class, something more industrial-esque. I quickly found another fun valve that could be used for a tail, and a piece of ducting to act as a body.

I saw at that point the allusion to one of my childhood favorite tv shows, Jimmy Neutron, in which the protagonist (Jimmy) has a robot dog he built named Goddard (there’s a picture of Jimmy and Goddard below).

I named my assortment of parts “Goddard” in honor of my childhood, hoping I would be able to evoke the same personality Jimmy was able to in the construction of his robotic companion.

Construction

I decide to start building, before having figured out what I am going to use for legs. Throughout this project, I wanted to use as few tools as possible, just to make the recycled theme feel more raw, less post-processed. For that reason, I didn’t cut the ducting (it wouldn’t have come out very good with a dremel and I didn’t want to use a bandsaw) leaving me with a wiener dog by necessity.

I first attached the head, which was actually fairly easy. I found another male-male nipple that could thread into the ducting, although the ducting wasn’t quite thick enough to hold a thread, so after drilling a hole I capped the other end with a similar pipe plug to hold it in place.

The mounting of the tail posed some difficulty, because the valve I had already had mounting holes built in, although they wouldn’t mount the valve at the right angle to mimic a tail. I entertained making a mating piece out of steel or aluminum for a while (I even had it made on CAD, see below), although again machining a piece from scratch kind of ruined the whole upcycling idea for me.

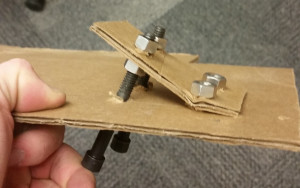

I went instead with a strange bolt-mounting scheme I thought might work. I really wasn’t sure about this actually, and so before I drilled any holes in the ducting I made a pretotype out of cardboard to see if I could potentially get two flat pieces to mount at an angle, and what I would need to do it. As it turned out, it would work fine, but I would need to slot the holes and use some spacers to hold the bolts in place.

I then drilled out some mounting holes and then dremeled them into slots, and the tail was mounted. Looking at just the upper part of Goddard, I thought he looked a little bare but overall kind of fun. I had found the legs at this point as well, 4 old suspension springs.

I’ll pause here for a moment and step back to talk about one of the difficulties in this design. I was using all hand tools to drill holes and slots into a steel cylinder, trying to be as accurate as possible along the entire length with only a pair of calipers and a pair of eyeballs. Mounting anything precisely was a huge difficulty; mounting these springs was another animal entirely. I had laid out a strip of tape laterally along the entire cylinder to serve as a centerline, although even that was never measured, only estimated.

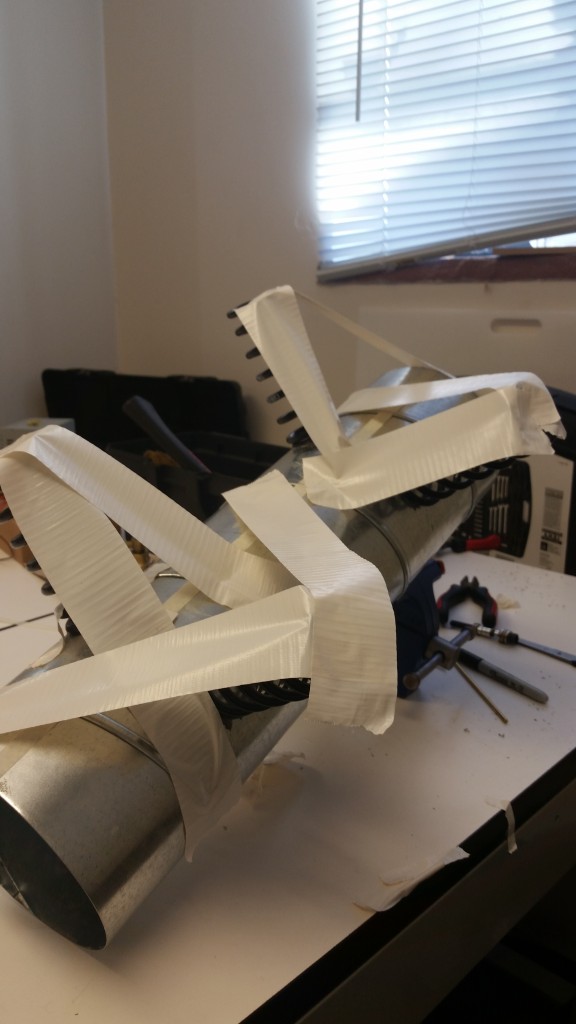

Again, I considered a mating piece between the spring and ducting but opted for simple adhesive, J.B. Weld, instead. I realized after mixing the adhesive I would have to tape the actual legs in place while it cured, something I hadn’t thought about at all. I ended up with a DIA looking tent structure of duct tape, which I had to just leave overnight and hope for the best. The springs were all placed in respect to the centerline, but due to their shifting and tendency to not stick perpendicular to the surface, I was stuck eyeballing as best I could. Given more time, I would have done each leg separately, but considering it is about a day to cure each I just did all at once.

The result was, as anyone with experience eyeballing will tell you, less than perfect. It took a few tries even to get the springs remotely close (I had to break off legs a few times and re glue to try to get a better fit – it was a very imperfect science). In the end, Goddard stands almost flat, close enough to dissuade me from trying to break off a leg and try to get it closer. He is, unfortunately, fairly lifeless. The springs are too far in, making him look less like a dog, and there is very little aesthetic appeal to the entire ducting. Maybe if the parts perfectly mimicked the canine form, it would be ok as a minimalistic piece but with the legs positioned as they are it looks somewhat awkward.

Future Work

I would change a few things about this if I were to do it again. First, I don’t think I need to make the process as rigid as I did. For some reason I thought the lack of power tools or additional manufactured components would make this a more authentic upcycle exercise. I was right and wrong, actually. Cutting the ducting a little bit would have given me a much more realistic looking piece, worth the nonexistent price of using a bandsaw. I did like, however, being forced to come up with a more creative mounting system for the tail valve than just machining a piece.

The J.B. Weld worked well enough, although it’s still a relatively fragile project, especially considering the stereotypical sturdiness of industrial parts. If I were to do it again, I’d want to weld the legs to the ducting (just a few tacks). This would be much stronger and look better as well.

Finally, I’d probably do something different with the body. The ducting isn’t an entirely bad idea, although the finish leaves the end product lacking personality. I tested using a dremel to add some texture (just sanding in lines to mimic fur), although that didn’t look perfect either and would have been very time consuming. I would also probably cover the ends; being able to see right through an animal is not a very natural appearance.

I did have some things I liked, though. I thought the overall combination of aesthetics was really interesting and fun, and had it been slightly higher quality I think this is still a really interesting idea. I realized also an interesting message industrial animals could convey, along the lines of society and technological advances subtracting from the personality and innate attraction to animal emotions. In this regard, I think the hollowness of the ducting actually shows this message much louder than if it were a solid body, turning this into an intentionally hollow animal that lacks emotion.

I also liked the simplicity; I still think machining parts takes away from the recycled feeling. Especially in an animal “sculpture”, taking all random parts found in the bottom of storage gives it an “adopted from the pound” personality; he’s just a mut. Making parts would give him way too much purebred. All in all, I think it’s a cool idea that didn’t get made to its full potential. I am planning on partial disassembly to try to reconstruct him into more of a dachshund. If all goes well, I think other animals made from industrial parts (birds, cats, cows, etc.) could be really fun and interesting.

43 Comments. Leave new

You gonna get some shag carpet on it?

I like the industrial look of your design. I also appreciate your commitment to sticking to little use of power tools. Have you thought about adding some amount of cloth to give it a more realistic animal look?

Awww, he’s adorable. Great idea for a project! The only thing I think he needs is a neck.

Really cool piece. You mentioned that Jimmy Neutron’s dog was inspiration for this project–I think more hybridization towards that character would be awesome!

What a mechanical engineer, finding “cute” valves! I like it! You should build on it and try to add lights or make it be able to move on wheels or something.

I think it’s awesome how you turned inanimate objects into something with such character. I don’t think welding would detract from the aesthetic as you are going for an industrial feel. Nice way to tie in the hollow body with a philosophical take on the project.

I love that the project is made from all recycled materials and uniquely creative appearance of a dog.

I love the reference to Jimmy Neutron, brings back some old memories. What if you drilled 1 hole for each leg and threaded the springs through? It might be sturdier than the JB weld

The body tube could use a dome cover or something, although your comments on it seemed interesting as well. It would be cool if the needles were symmetric. Good work!

High art. Name your price. Perhaps the hollow body could be a candle holder.

Awesome idea, I definitely watched and enjoyed Jimmy Neutron as a kid.

Really great idea from the inspiration to the implementation. Goddard would be a great addition to anybody’s industrial animal collection.

Good job. I like your idea to leave him in the idea forge.

This is great! He really is cute. You should build a house for him. Have you considered using items to make it move such as a spring in the tail?

I really like the inspiration of this project. I think that you really did get to a “cute” look out of this. Overall good, job!

I like that you were dedicated to strictly upcycling throughout the project and trying not to use many tools.

Awesome puppy!!! May not be great for cuddling with but I really like the aesthetic.

Neat dog – maybe he’ll find a home somewhere in the idea forge!

awesome idea. I think welding would have help for the future but it turned out just as good

I love the upcycled pet look, and you nailed it! You did a great job of personifying scrap.

Cool project, I like that you recycled 100% of your parts. Also, I enjoyed your commentary on this.

This reminds me of the animals that you see in some shops on Pearl street that are made of welded washers, springs and gears. This could be a fabulous piece of garden artwork. I really like the simplicity and industrial feel. Nice work Matt!

The dog looks great! Do you think Daria would let you keep it in the idea forge?

I do like the idea of reducing how hollow the main body is, but whatever is chosen shouldn’t distract from the rest of the upcycled parts because they are cool!

That is a very cool project and the process of creating it was very inserting.

I really like the inspiration of building around one component. I appreciate that you kept upcycling as something simple, and mostly re-purposing stuff that would otherwise be thrown out. I’m a fan of the craftiness to this and that it’s art for the sake of art.

The fact that your inspiration was seeing a valve and thinking that it was “cute” is fabulous. I also like that you made Goddard. It seems that industrial animal yard art is popular these days. It’s a fun idea and turned out well.

The springs used as legs adds a great touch to the pup. Does he know any tricks?

I love the Jimmy Neutron inspiration! I really like your different approaches of the deeper meaning of your project. Very fun idea and a very cheap and easy pet!

I really like where you got your inspiration, looking at various parts that brought your design together. It is cool that you took parts that don’t relate to a dog, but you took an interesting twist on it. It reminds me of the aluminum motorcycle design,, but on a larger scale. I also liked your philosophical statement as well.

I like the parts. Good job on cleaning the parts. Great and simple presentation. Good explanation of the process. I like it not covered up. I think it looks better this way. My favorite part is the face. Legs are also nice. Good job

The face valve is pretty darn cute. Would love to see a second interation or your next animal build.

I love the regulator as face! and frou-frou tail. I admire the process aesthetic and how that shaped the final design. I like the ‘hollow’ commentary too.

Interesting aesthetic, reminds me of metallic chickens and such you see in farm country, like the minimal use of power tools or 3-d printing. Staying true to form is always integral to artistry.

I like your hollow weiner dog made from parts stolen from Narnia.

Me too

Love Jimmy Neutron! I like how you kept the up-cycling feel throughout your project and really did use goddard as your inspiration with springs as legs and everything!

So cool looking! Very industrial looking while still having the animal like look. Great reuse of some old hardware. Do you have any ideas on what you would use to cover the ends of the ducts.

Goddard turned out well and I agree that you turned an industrial part into something too great job and I like the uniqueness of this project.

great job and I like the uniqueness of this project.

I remember this show. This is a nostalgia trip for me. This project looks cute and awesome! This is a fun project, good job. The gage eyes are cool.

great find on that valve, it def looks like a dog face. good stuff man!

How adorable! I like that you decided to make Goddard completely out of metal parts, it really lends him a good robot aesthetic.

Sorry all to make you strain your eyes on that last photo of the taped legs, it isn’t rotating or enlarging in the blog.